Ace Pipe Cleaning

Ace Pipe Cleaning successfully completed a job in the City of Forth Worth that involved installing Warren coating on a new Lake Arlington Lift Station. The project is owned by City of Fort Worth and was designed by Freese and Nichols.

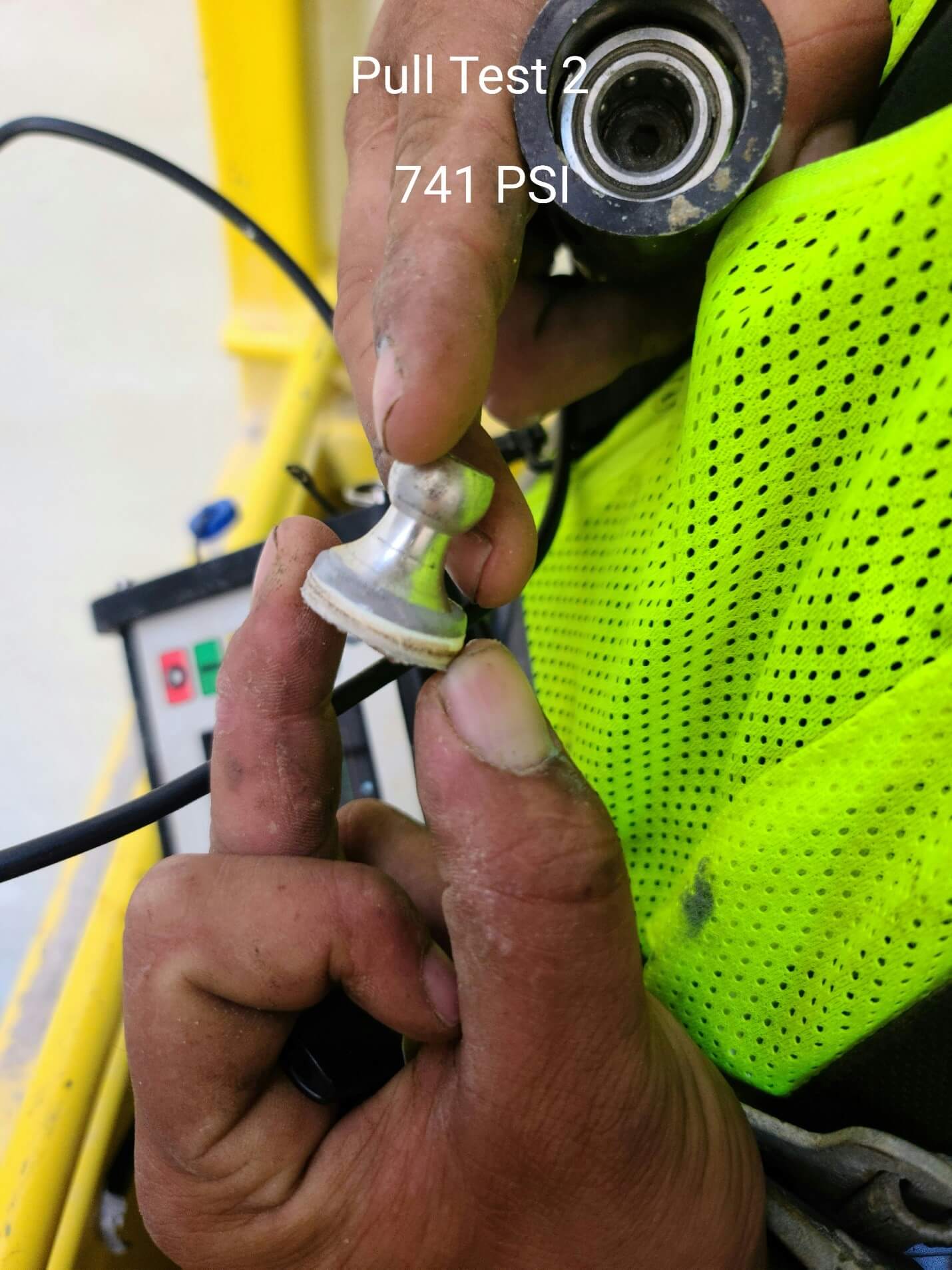

The trench-style wet well is roughly 61’ x 19’ x 48’ deep and the protective coating was specified at 125 mils (Warren or Chesterton). The post application testing included spark testing and required 30 adhesion pull tests (per ASTM 7234) across the entire coating surface. ASTM 7234 requires drilling a core down to the substrate, gluing a metal dolly and pulling the dolly until it yanks the coating off the wall. Typically pull test values that exceed 300 psi are required. For this project, the average pull test value was greater than 550 psi, which is one of the standout characteristics of Warren coating.

The concrete wet well was originally formed and a few weeks later the concrete roof was constructed. All concrete was cured 28 days prior to coating activities. A multi-level scaffolding was installed, and all of the new, smooth concrete was sandblasted to achieve a good profile for the coating product. Coating activities started at the roof and continued level by level to the bottom of the wet well. Proper surface preparation is tedious and time consuming and many coating failures can be traced back to the performance of this critical step. However, everyone was pleased with the thoroughness of the surface preparation and application process performed by Ace Pipe Cleaning, which ensured the success of the coating.