National Power Rodding

National Power Rodding (NPR) recently completed a project for the Village of Forest View, Illinois. The village asked NPR to investigate a tunnel shaft that served as a conduit for a 12-inch diameter watermain. The village knew there was water infiltration but was unsure of the source.

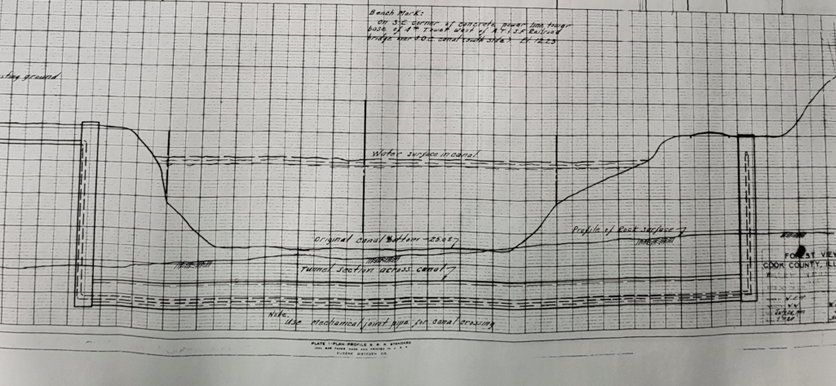

The watermain was 100 feet underground and ran under the Chicago Sanitary and Shipping Canal, adding significant complexity to the project. The watermain feeds fresh water from the south side of the town to the north sid,e about 40-50 feet under the riverbedThe only way to reach and inspect the line was through the 6×5-foot diameter tunnel shaft, down to a 12-foot arched tunnel running underneath the canal about 400 feet long. The last time the watermain had been inspected was in 1980 by the local fire department and trained divers.

When NPR arrived on site, they found that both the north and south side shaft were filled with 80 feet of water that would have to be pumped out in order to access the tunnel. Once the shaft and tunnel were dewatered, they discovered the watermain was still under pressure and leak free. Inspections found the leaks were actually in the base and sides of the tunnel due to ground water infiltration. These leaks would need to be grouted by hand using a grout gun. The NPR team drilled several 2-inch holes in concrete 18 inches thick with a 2-foot head on the grout gun to stop the leaks.

Due to the depth of the project and confined space concerns, a number of safety protocols were put in place prior to addressing the tunnel issues. A pre-launch safety plan was drawn up defining everyone’s role and confined space retrieval equipment was ordered. First, a test run was performed using cameras only. Then, the crew was tethered and lowered down the shaft into the tunnel. Four crewmembers were working in the tunnel out of a crew of twelve people. Rescue and ventilation personnel were on both sides of the river. The crew was equipped with flotation devices, life vests, gas detectors and escape packs. Air quality was monitored, and blower fans were used to provide fresh air. Two cameras were on at all times capturing all work providing a live feed to the crew above ground.

Another safety concern was the environmental impact of the water pumped from the shafts into the river. The EPA was called in and took samples of the water. Once they were okay with the results, the water was pumped into the river.

It took seven months to plan and execute the project, with seven trucks and twelve crew members. The job itself only took four days to dewater, pre-inspect, stop the infiltration and then do a final inspection of the job, proving that detailed planning is critical to a successful outcome and a happy customer.